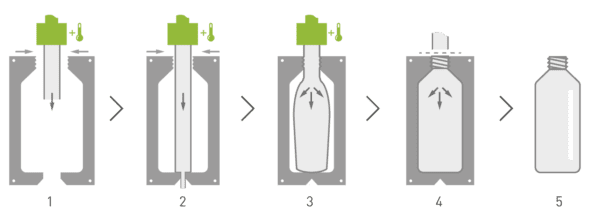

EXTRUSION BLOW MOULDING

BIOBASED AND COMPOSTABLE POLYMERS FOR BOTTLES AND SINGLE-SERVE CONTAINERS

Extrusion blow moulding is used to produce hollow parts such as bottles and containers. In this manufacturing process, the polymers are melted and extruded into a hollow tube, known as a parison. This parison is closed in a cold metal mould. When air is blown into the parison, the hollow part is formed. The piece is then cooled and finally ejected.

INZEA® presents a specially developed biopolymer for extrusion blow moulding that can be processed on conventional lines. Thanks to their compostability and renewable content, INZEA biopolymers are the optimal solution for any type of food packaging.

INZEA Processing Recommendations for Extrusion Blow Moulding

Traditionally, blow moulding is used for the manufacture of bottles and containers.

Whenprocessing INZEA grades by extrusion blow moulding for any application, a melt temperature of 190°C is recommended and the moulded parts should be kept at a low temperature.

OK COMPOST Certification for bottles

Sustainable bottlesare now possible thanks to 100% compostable INZEA biopolymers. Our entire range of INZEA products is OK Compost certified, according to the European standard EN 13432.

Single-use bottles can be recovered together with organic waste to produce compost.

Key benefits

- Moulding complex parts

- Biobased content

- Ok Compost

- Suitable for food contact

Biodegradable bottles and containers suitable for food contact

WHAT IS INZEA

The world is changing and the plastics industry has to adapt to a new situation where sustainability is a priority for governments, businesses and consumers. INZEA® is our response to our customers’ demand for more sustainable plastic materials.

INZEA is a range of biopolymers which can replace traditional plastics in different applicationssuch as bags, mono-use items and packaging, with the advantage of being biodegradable and compostable.

INZEA product range is obtained from renewable sources and is designed to return to nature by different disposal methodslike industrial & home composting, or by biodegradation in different environments.

APLICATIONS

Bottles

INZEA® has suitable grades for the production of compostable bottles by both injection and extrusion blow moulding, without varying the manufacturing parameters.

Detergency and phytosanitary packaging

There are INZEA® grades suitable for phytosanitary and detergency applications, which have the advantage of being biodegradable at the end of their useful life, thus minimising the impact on the environment if not properly managed.

Natural cosmetics packaging and consumables

There are INZEA® grades suitable for the packaging of cosmetic and natural detergent products, both solid and liquid, with the advantage of being biodegradable at the end of their shelf life.

SOLUTIONS

Want to stay updated on the latest on NUREL Biopolymers?

Subscribe to the Newsletter